Auto Measuring System

-

ENGINE PART

- Connecting Rod

- Cylinder Block

- Piston & Piston pin

-

MISSION PART

- T/M Shaft

- T/M Case type, Gear type

- Outer Race

-

DRIVING & BRAKING PART

- Brake Disk & Drum

- Hub Bearing

- C/V Joint

- Axle ass’y

-

STEERING PART

- Worm & Worm wheel

- G/Box HSG

- Quill ass’y

- Input & Pinion shaft

-

OTHERS PART

- Compressor Parts

- Turbo-charger Parts

- Bearings Parts

- etc…

- A. 100% inspection system of major car parts at final process

- B. Storage and classification of measured data, SPC system management

- C. Measuring system establishment optimized to production process and item

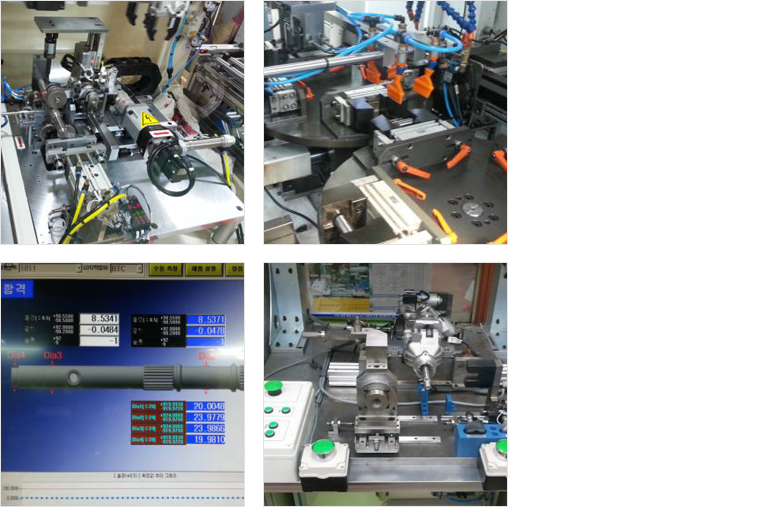

A. Inner diameter measuring system of BJ outer race

-

Items to be inspected

- PCD (ø66.10 0/+0.07)

- Inner diameter (ø73.78 0/+0.03)

- The deepest point of track (52.145±0.02)

- Track diameter, the deepest point of inner race

Installed at KOREA FLANGE Co., Inc.

B. Piston ring-home measuring system

-

Items to be inspected

- Inclination of top & 2nd & 3rd Ring-home of piston

- Roundness (ovality) of piston

Installed at DONG YANG PISTON Co., Ltd

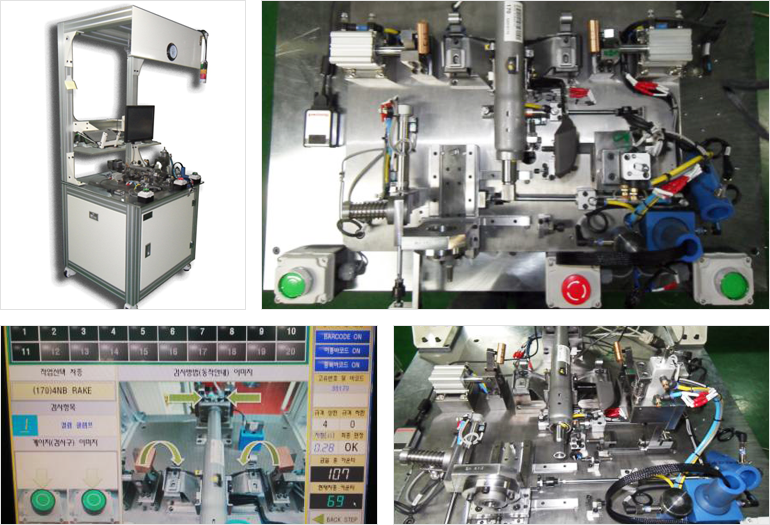

C. Column comprehensive inspection system

-

Items to be inspected

- Model : EM ONIX comprehensive inspection

- Tilting test, lever clamping force & motion test, current carrying test

- Automatic barcode reading system

Installed at Namyang Industry Co., Ltd.

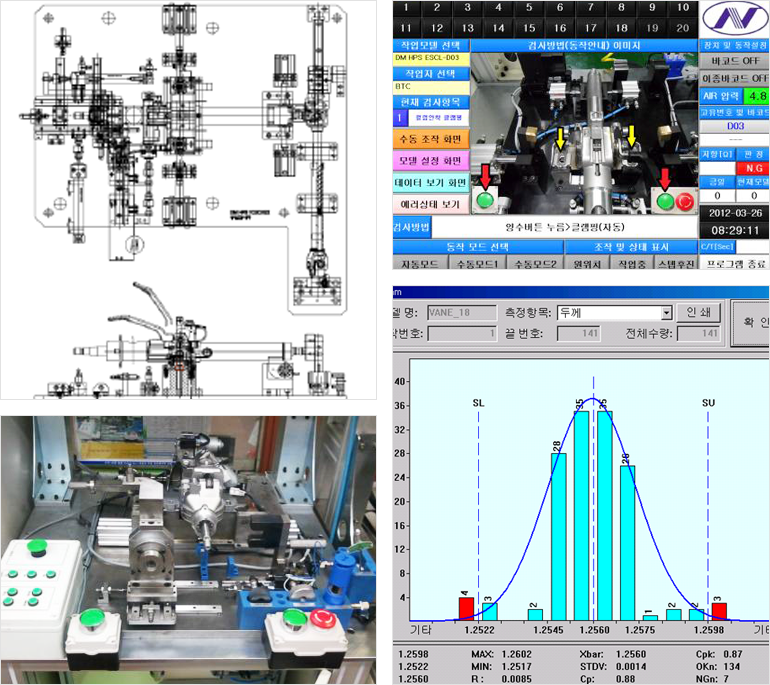

D. HPS inspection system

-

Items to be inspected

- Screw test, screw thread test, lever clamping force & motion test, current carrying test

- Jig is replaced item by item

Installed at Namyang Industry Co., Ltd.

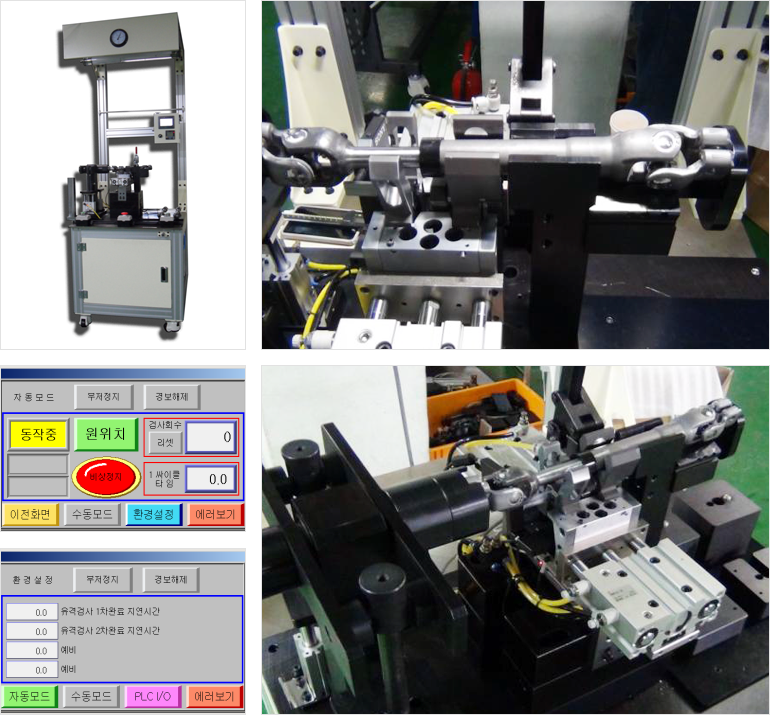

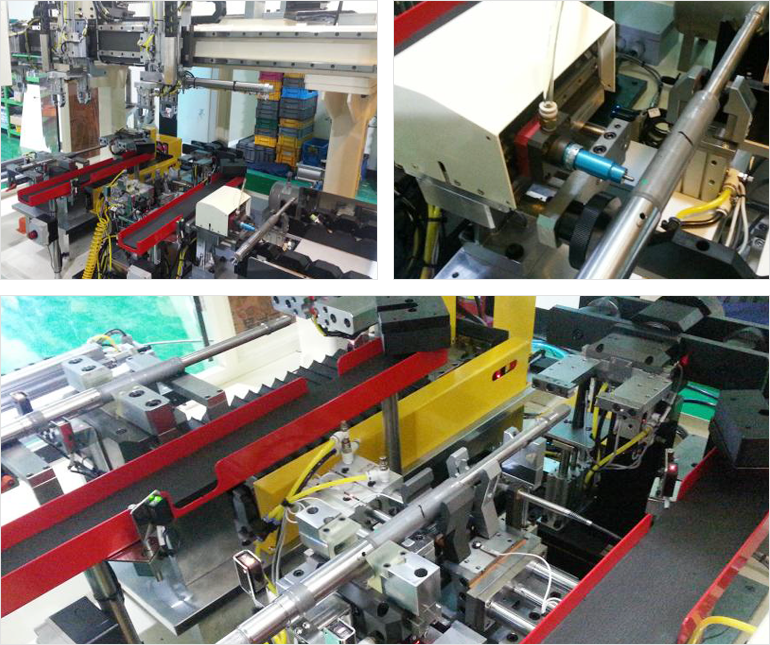

E. Break sorter for steering U-JOINT SHAFT

-

Installed at Namyang Industry Co., Ltd.

- It measures the broken space between the fixed tube and the rotating shaft

- Jig is replaced item by item

Installed at Namyang Industry Co., Ltd.

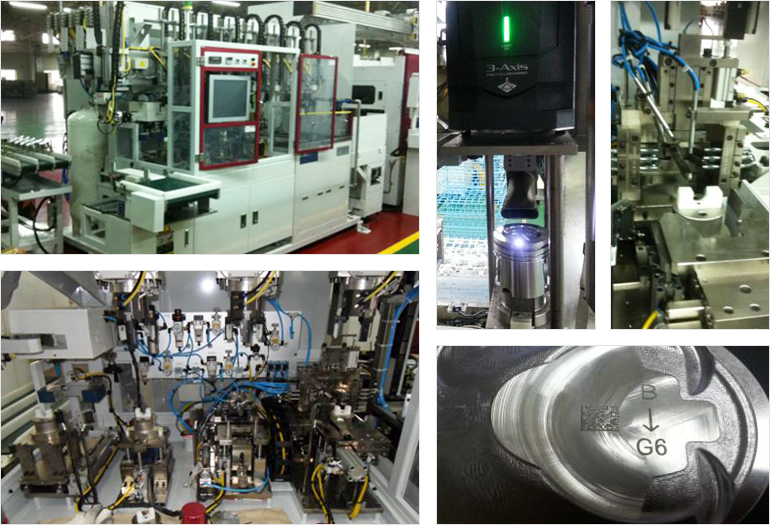

F. Automatic marking system for BJ outer race

-

Items to be inspected

- Automatic marking system using exclusive marking controller

- Year, month, date, day/night, serial no., etc. are automatically changed

- If model is changed, position and angel are adjusted.

Installed at KOREA FLANGE Co., Inc.

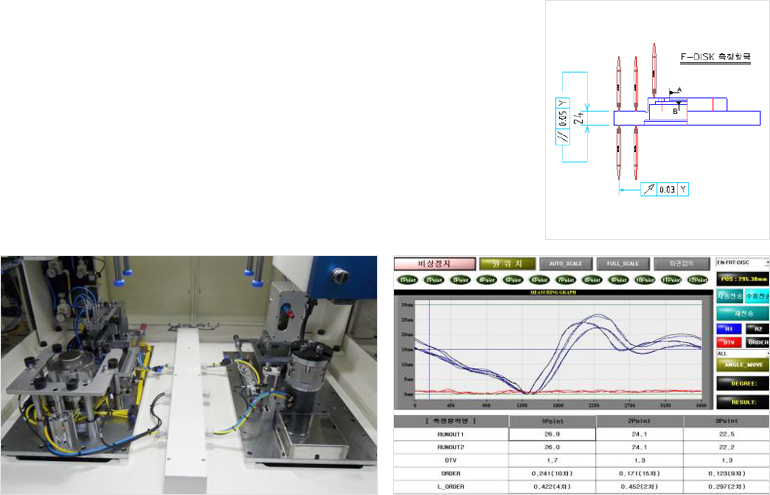

G. Measuring & marking system for brake disc

-

Items to be inspected

- Runout (5 point), DTV (2 point), flatness (2 point), ORDER, FRF

-

Inspection conditions

- Automatic cleaning and rust-preventing are included

- 100% inspection, inspection result is automatically marked (Dot & Laser)

-

Precision

- Sensor precision 0.2 um, runout tolerance 2 um, DTV tolerance 1 um

Installed at Namyang Industry Co., Ltd. and Delphi Korea

H. Measuring & marking system for steering shaft

-

Items to be measured

- Tensile strength & compressive strength

- It measures torsion between tube and shaft

- Torque test by using road cell

- Automatic marking of lot no. & serial no

Installed at Namyang Industry Co., Ltd.

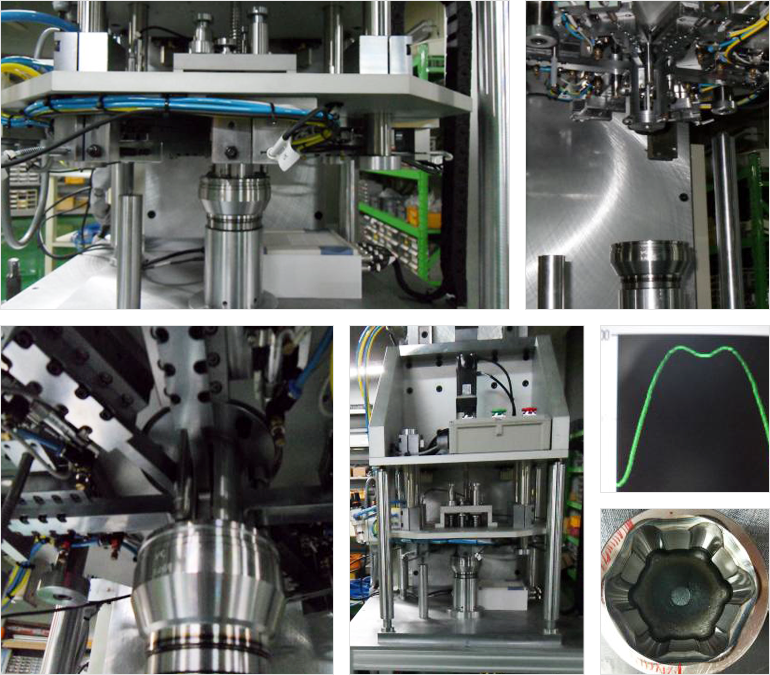

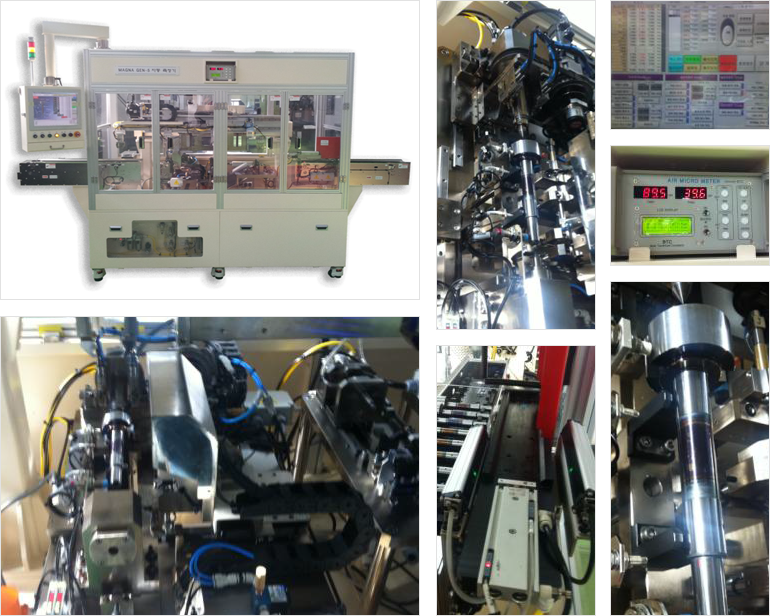

I. Piston grade sorter

-

Items to be inspected

- Outer diameter, pinhole, weight, ultrasound

- Grade is automatically marked

-

Inspection conditions

- Automatic cleaning, 100% inspection, inspection result is automatically marked (Dot & Laser)

-

Precision

- Repetitive error (1 um)

Installed at DONG YANG PISTON Co., Ltd

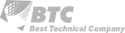

J. Piston pin inspection system

-

Items to be inspected

- Outer diameter (4 point), full length (1 point), laser marking

-

Precision

- Sensor precision (0.2 um), repetitive error (1 um)

Installed at DONG YANG PISTON Co., Ltd. and Sung Il M-Tech

K. Gen-5 shaft measuring system

-

Items to be inspected

- Outer diameter, inner diameter, point to be processed, amount to be processed and crack

-

Inspection conditions

- Ultrasonic automatic cleaning & 100% inspection, sorting defected items by type

-

Precision

- Sensor precision (0.2 um), repetitive error (2 um)

Installed at Seoul Industry Co., Ltd.

L. Magna shaft inspection system

-

Items to be inspected

- Outer diameter (4 point), inner diameter (1 point), screw, if processed or not

-

Precision

- Sensor precision (0.2 um), repetitive error (2 um)

-

Inspection conditions

- Ultrasonic automatic cleaning & 100% inspection, sorting defected items by type

Installed at Seoul Industry Co., Ltd.

M. Automatic BAR measuring system

-

Items to be inspected

- length

- thickness

N. GEAR measuring system

-

Items to be inspected

- OBD

- T/R

- TOOTH to TOOTH

O. LASER measuring system

-

Items to be inspected

- bending and flatness of cell phones, DVD Plate, etc.

- Setting points and items to be measured available

P. MANUAL PISTON GRADE sorter

-

Items to be inspected

- outer diameter of piston, pinhole, valve point, compression height, marking

Q. QUILL SHAFT WASHING MACHINE

-

Items to be inspected

- Ultrasonic cleaning and air blow for Quill Shaft