Non-destructive Inspection System

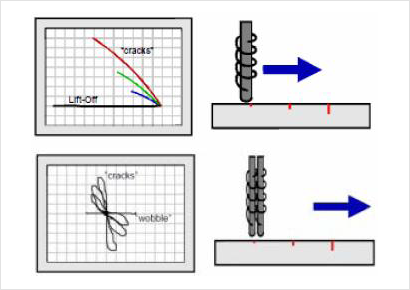

- Eddy current inspection system

- crack inspection (crack, overlap and breaking etc.)

- heat treatment inspection (poor heat treatment, poor hardness etc.)

- material inspection (different material or different kind, etc.)

- Installed at DONG YANG PISTON Co., Ltd. and Sung Jin FO-MA Inc etc.

Heat treatment inspection of Piston pin

Crack inspection of bearing inner race

Piston Crack Inspection

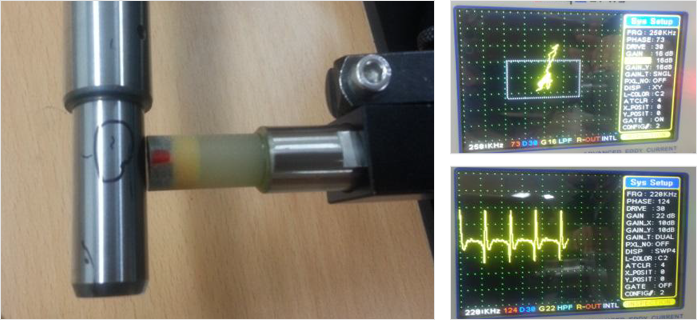

Crack inspection of GEN-5 SHAFT

When high-frequency current flows through the coil, eddy current is created. It is a non-destructive inspection method by detecting and analyzing the eddy current distribution change influenced by defect.

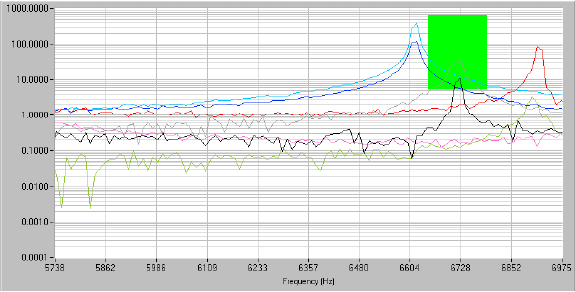

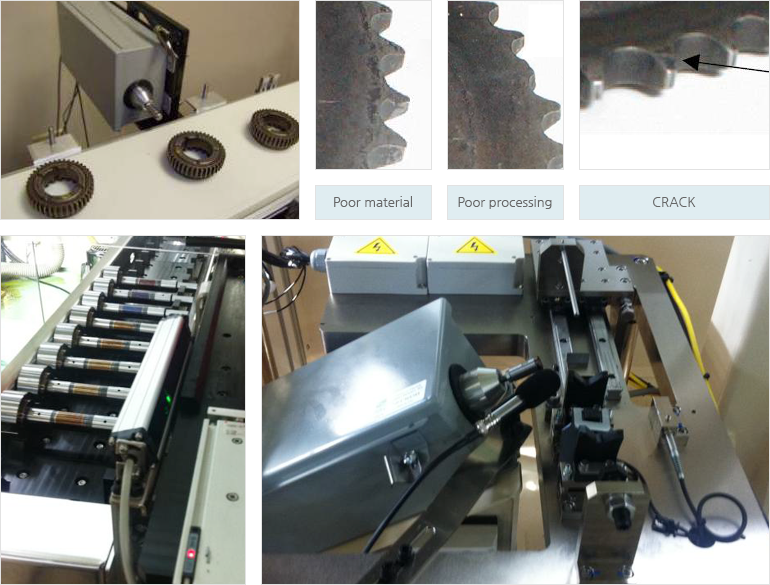

- Acoustic resonance inspection system

- crack inspection (crack, overlap and breaking etc.)

- heat treatment inspection (poor heat treatment, poor hardness etc.)

- material inspection (different material or different kind, etc.)

- processing inspection (poor processing, poor raw material etc.)

- Installed at Seoul Industry Co., Ltd., and Namyang Industry Co., Ltd., etc.

- Features of acoustic resonance inspection system

- Contactless high speed inspection available

- Inspections for material, processing, different kind, etc. available by the response of natural frequency of product

- Simple system